Product

제품

PODUCT INFO

Optics

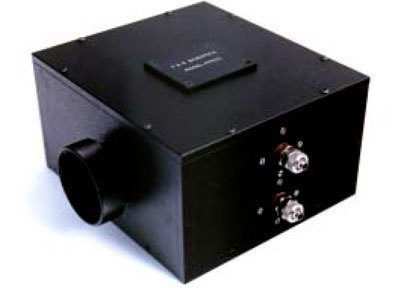

FPR25 In-Line Phase Retarder Unit

FPR25 In-Line Phase Retarder Unit

Introduction

The FPR25 is an in-line phase retarder assembly for conversion of linear to circular polarization. A

copper-based phase retarder λ/4 (90 degree) type is used to effect the polarization conversion, and

three zero phase mirrors follow in order to steer the beam back into its original path. By virtue of

the in-line design, model FPR25 can easily be retro-fitted into existing laser equipment without the

necessity of moving either the laser, or subsequent equipment, due to the inclusion of a ‘dogleg’ into

the beam path. Model FPR25 has a 33mm clear aperture and will withstand high CW CO2 laser

powers.

Technical specifications

Dimensions : See Figure 71.11

Fittings : Standard free-rotating coupling rings with 52.0 x 1.5 pitch thread.

Water cooling : 8/6 size input/output fittings. Water is internally distributed.

Alignment : Factory set to < 1 minute of arc.

Phase retardation : 90 degrees ± 5 degrees (λ/4).

Clear aperture : 33mm diameter.

Wavelength : 10.6μm

Max power : 5kW CW

Associated equipment

Model FPR25 is a direct fit to OPG piping (Section 61.1) and to lateral adjustment units LAU25

(Section 72.1) and LAM25 (Section 72.2). If variable, or ‘tunable’ output polarization is required,

then model FPR25 may be used in conjunction with the manual polarization rotator, model BPR25.

Used in this format, Laser – BPR25 – FPR25, the output polarization can be varied between linear,

through elliptical, to circular. Rotation of the azimuth of the FPR unit about the optical axis allows

the major axis of emitted elliptical polarization to be in any desired plane. The manual beam

polarization rotator is described in Section 73.1.

Applications notes

1) Some industrial CO2 lasers, (eg. Electrox type), have a built-in phase retarder within the laser box.

In order to use various optical devices which rely on processing a linearly polarized beam, such lasers

require re-conversion to emit linear polarization. This is easily done by replacing the installed phase

retarder component with a mirror. Processes where this may be necessary include:

Isolation of the cavity from back-reflected beams.

Attenuation using Brewster plates.

Beam sampling using (modified) Brewster plates.

Laser power stabilization using Brewster plates.

Polarization steering techniques.

2) Model FPR25 is specifically for CW CO2 lasers emitting a wavelength of 10.6μm. A broadband

version for tunable CO2 lasers is detailed in Section 71.2.

3) The FPR25 ‘box’ must be set at 45 degrees azimuth angle (rotation about the optical axis) to the

plane of the incident linear polarization.